Couterweights

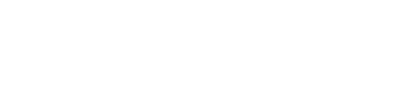

The Mesu Mount has a 40 mm counterweight shaft. I did not want to spend the extra money shipping counterweights from the Netherlands. There are dealers in the USA who carry counterweights for 40 mm shafts (i.e., for some 10Micron mounts) but I’m too cheap to pay for those plus shipping. So I ended up making my own. I ordered thick steel tubing from Midwest Steel and Aluminum (Rogers, MN). I ordered 2 sets of the following: (outside diameter followed by thickness) 2” x 3/16”, 3” x 3/8”, 4” x 3/8”, 5” x 3/8”, and 6” x ½”. All pieces were cut to a length of 3.5 inches and I was able to pick them up rather than have them shipped. The total weight of steel for each weight was about 22.3 lbs. I drilled a hole in the side of each piece (1/2 inch for the 2, 4, 5 and 6 inch pieces) and I tapped a 5/16 x 18 hole in the 3 inch pieces. I stacked the respective diameters one inside the other, lining up the holes. I had to do some grinding/sanding on the outside of the 5 inch pieces to get them to fit inside the 6 inch tubes. With the pieces evenly spaced I poured JB Weld in the spaces (I added a bit of acetone to thin the JB Weld out – see www.jbweld.com). I had the bottom sealed with tape and a bolt threaded though the hole and tap to the inside surface of the 2 inch diameter tube. I sealed off the remaining space on the outside and inside of the drilled out hole with tape. For each weight I used about 2 packages of the 5 oz package size of JB Weld. After it set, I removed the tape and tested unscrewing and screwing in the bolt to make sure it wasn’t stuck. I then primed and spray painted the weights. The 2 inch x 3/16 inch thick tube has an inside diameter of about 1.625 inches. The 40 mm shaft is about 1.575 inches so the weight fits nicely (not too tight) on the counterweight bar. The total weight of each counterweight (steel, epoxy, bolt) is about 22.5 lbs

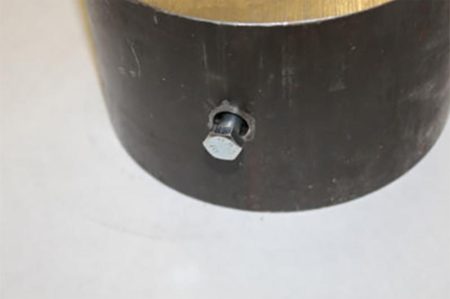

You can see, in the picture above, the tip of the bolt coming out of the smallest steel tube. All rings except the second smallest, have ½ inch holes drilled out to allow passage of the tightening bolt. The second smallest tube was tapped (5/16 x 18) and a hex-head bolt was used as the counterweight tightening bolt,